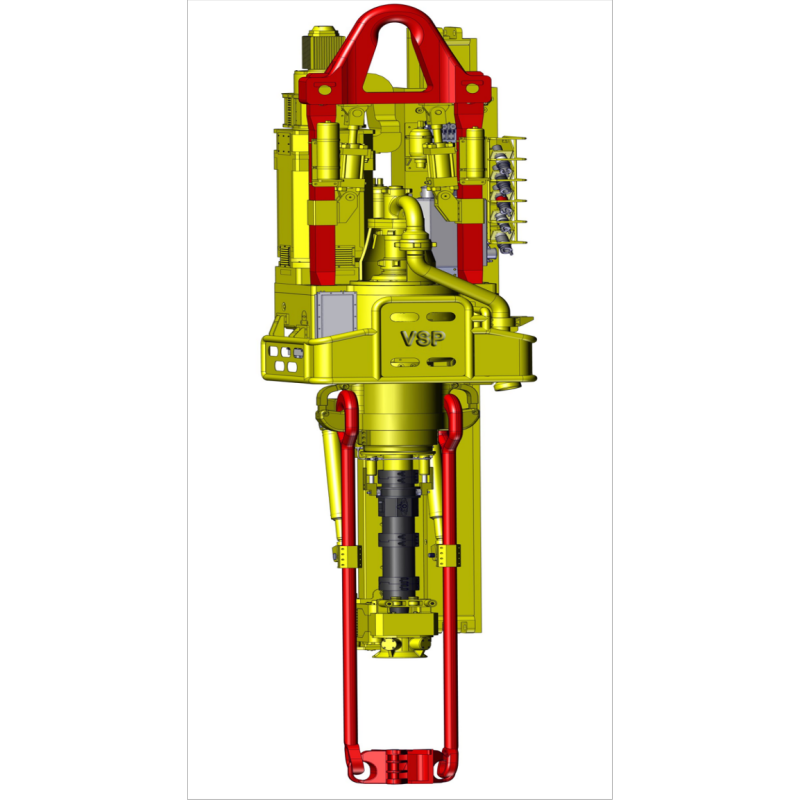

The full name of TDS is TOP DRIVE DRILLING SYSTEM,the top drive technology is one of several major changes since the advent of rotary drilling rigs (such as hydraulic disc brakes, hydraulic drilling pumps, AC variable frequency drives, etc.).Since the early 1980s, it has been developed into the most advanced integrated top drive drilling device IDS (INTEGRATED TOP DRIVE DRILLING SYSTEM), which is one of the outstanding achievements in the current development and updating of drilling equipment automation.It can directly rotate the drill pipe from the upper space of the derrick and feed it down along a dedicated guide rail, completing various drilling operations such as rotating the drill pipe, circulating drilling fluid, connecting the column, making and breaking the buckle, and reverse drilling. The basic components of the top drive drilling system include IBOP, motor part, faucet assembly, gearbox, pipe processor device, slide and guide rails, driller’s operation box, frequency conversion room, etc.This system has significantly improved the ability and efficiency of drilling operations and has become a standard product in the petroleum drilling industry. Top drive has many significant advantages. The top drive drilling device can be connected to a column (three drill rods form one column) for drilling, eliminating the conventional operation of connecting and unloading square drill rods during rotary drilling, saving drilling time by 20% to 25%, and reducing labor intensity for workers and personal accidents for operators. When using the top drive device for drilling, the drilling fluid can be circulated and the drilling tool can be rotated while tripping, which is beneficial for handling complex downhole situations and accidents during drilling, and is very beneficial for drilling construction of deep wells and special process wells. The top drive device drilling has transformed the appearance of the drilling rig’s drilling floor, creating conditions for the future implementation of automated drilling.