Drill Rig Matching Equipment

-

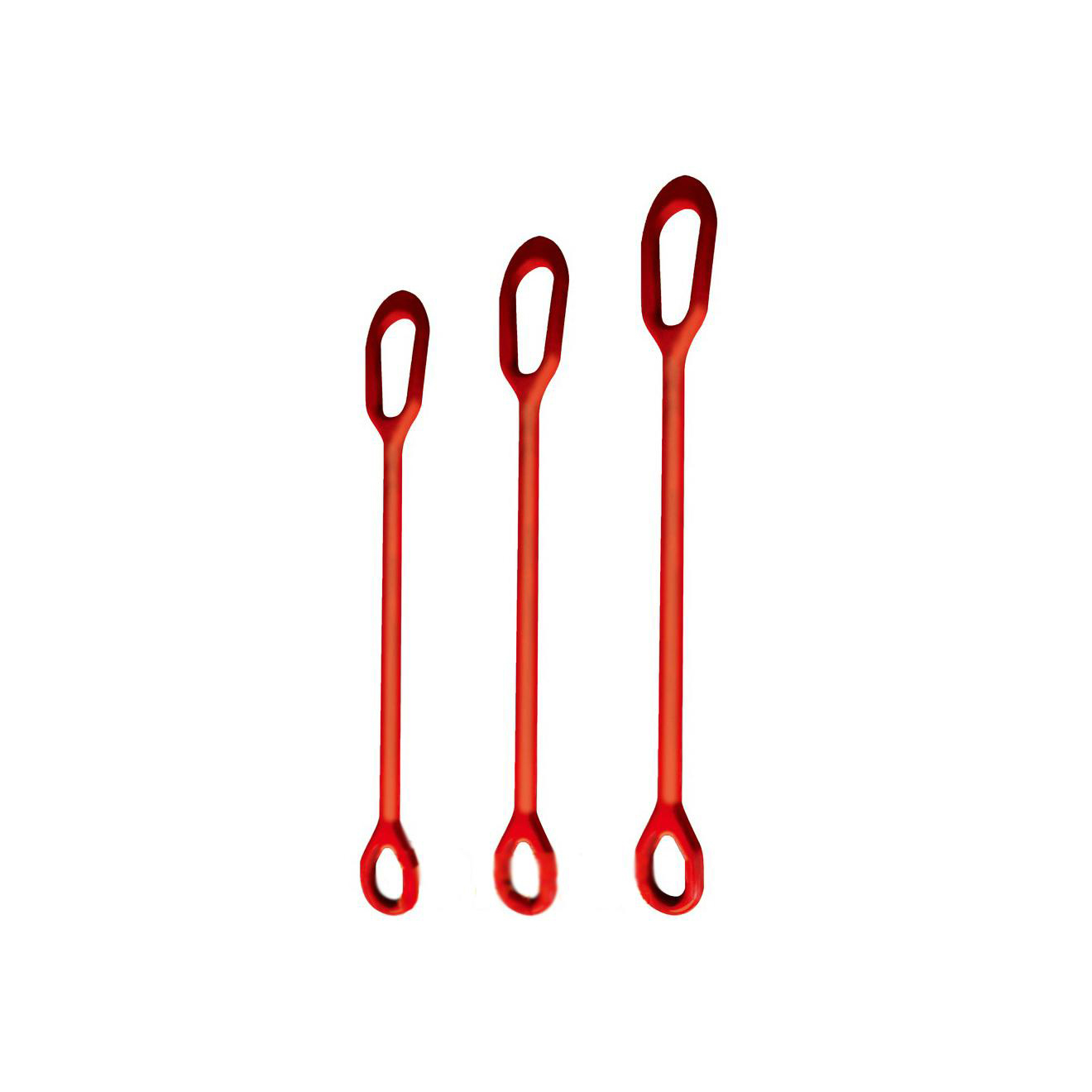

30180389 10490415-315 10490416-756 122599 TDS8SA TDS11SA Elevator Link for NOV VARCO TDS

VARCO:tds11sa,tds9sa,tds8sa,etc.

TESCO: HXI HCI HS ECI EMI EXI

CANRIG:1035 1050 1250 8050 6027

HH: DQ225DBZ DQ315DBZ DQ450DBZ DQ675DBZDQ900DBZ DQ225Z DQ450Z

JH: DQ40B DQ50B DQ50BQII-JH DQ70BS

BPM: DQ40BC DQ50BC DQ70BSH DQ70BSC DQ70BSD DQ80BSC DQ9OBSC

TPEC: DQ40AIII-A DQ40LHTY-LA DQ50II-A DQ50II-A DQ7011I-A DQ90I

Price and delivery: Contact us for detailed quotation

-

30180389 10490415-315 10490416-756 122599 Elevator Link for hanging Elevator from TDS8SA TDS11SA

VARCO:tds11sa,tds9sa,tds8sa,etc.

TESCO: HXI HCI HS ECI EMI EXI

CANRIG:1035 1050 1250 8050 6027

HH: DQ225DBZ DQ315DBZ DQ450DBZ DQ675DBZDQ900DBZ DQ225Z DQ450Z

JH: DQ40B DQ50B DQ50BQII-JH DQ70BS

BPM: DQ40BC DQ50BC DQ70BSH DQ70BSC DQ70BSD DQ80BSC DQ9OBSC

TPEC: DQ40AIII-A DQ40LHTY-LA DQ50II-A DQ50II-A DQ7011I-A DQ90I

Price and delivery: Contact us for detailed quotation

-

Heavy-Duty Drawworks for Enhanced Drilling Efficiency and Durability

Model NO:JC40/JC50/JC70

Certification:CE, RoHS, ISO 9001:2000, ISO 9001:2008, API

Specification:45t

-

Heavy Duty TDS-11SA Drawworks for Top Drive Parts

Model NO:JC40/JC50/JC70

Certification:CE, RoHS, ISO 9001:2000, ISO 9001:2008, API

Specification:45t

-

![[Super cost-effective] Second-hand Coiled Tubing Unit](https://cdn.globalso.com/tdsparts/车4.jpg)

[Super cost-effective] Second-hand Coiled Tubing Unit

Brands:Jereh

Condition: Reasonable working hours; key systems (hydraulic, control, power) operating smoothly

Maintenance Records: Fully documented with no major incidents

-

AC Variable Frequency Drive Drawworks

The main components of drawworks are AC variable frequency motor, gear reducer, hydraulic disc brake, winch frame, drum shaft assembly and automatic driller etc, with high gear transmission efficiency.

-

Mechanical Drive Drawworks on Drilling Rig

Drawworks positive gears all adopt roller chain transmission and negative ones adopt gear transmission. Driving chains with high accuracy and high strength are forced lubricated.

-

Swivel on Drilling Rig transfer drill fluid into drill string

The drilling Swivel is the main equipment for the rotary circulation of the underground operation. It is the connection between the hoisting system and the drilling tool, and the connection part between the circulation system and the rotating system. The upper part of the Swivel is hung on the hookblock through the elevator link, and is connected to the drilling hose by the gooseneck tube. The lower part is connected with the drill pipe and the downhole drilling tool, and the whole can be run up and down with the traveling block.

-

DC Drive Drawworks of Drilling Rigs High Load Capacity

Bearings all adopt roller ones and shafts are made of premium alloy steel. Driving chains with high accuracy and high strength are forced lubricated. The main brake adopts hydraulic disc brake, and the brake disc is water or air cooled. The auxiliary brake adopts electromagnetic eddy current brake(water or air cooled) or pneumatic push disc brake.

-

Crown Block of Oil/Gas Drilling Rig with Pulley and Rope

The sheave grooves are quenched to resist wear and extend its service life. The kick-back post and rope guard board prevent the wire rope from jumping out or falling out of the sheave grooves. Equipped with safety chain anti-collision device. Equipped with a gin pole for repairing the sheave block.

-

Hook Block Assembly of Drill Rig high weight lifting

The hook block adopt the integrated design. The traveling block and the hook are connected by the intermediate bearing body, and the big hook and the cruiser can be separately repaired.

-

Traveling Block of oil drilling rigs high weight lifting

The Traveling Block is an important key equipment in the workover operation. Its main function is to form a pulley block by the sheaves of the Traveling Block and the mast , double the pulling force of the drilling rope, and bear all the downhole drill pipe or oil pipe and workover instruments through the hook.