Case

-

Valve Assembly Mud pump Valve Supplier API Standard Mud Pump Part F1600 F800 F1300

For Mud pump, the Brand and Model we can supply:

BOMCO / HONGHUA (China): F-500, F-800, F-1000, F-1300, F-1600, F-1600HL, F-2200HL

Continental Emsco (USA) : F-350, F-500, F-650, F-800, F-1000, FB-1300, FB-1600

Gardner Denver (USA) : TEE, PAH, PA-7, PZ-8, PZ-9, PZ-10, PZ-11

Ideco (USA) : T-500, T-800, T-1000, T-1300, T-1600

National (USA) : 7-P-50, 8-P-80, 9-P-100, 10-P-130, 12-P-160, 14-P-220

Oilwell (USA) : A-850-PT, A-1100-PT, A-1400-PT, A-1700-PT

Cameron-LEWCO (USA): WH1312, WH1612, W2200, W2214, W2215

MH Wirth (Germany): TPK-1600, TPK-2200

-

Triplex Mud Pump Fluid End Parts/Hydraulic Cylinder Bomco/Emsco/Gardner Denver/Tsc/Oilwell/Nov Drilling Mud Pump Parts

The Brand and Model we can supply:

BOMCO / HONGHUA (China): F-500, F-800, F-1000, F-1300, F-1600, F-1600HL, F-2200HL

Continental Emsco (USA) : F-350, F-500, F-650, F-800, F-1000, FB-1300, FB-1600

Gardner Denver (USA) : TEE, PAH, PA-7, PZ-8, PZ-9, PZ-10, PZ-11

Ideco (USA) : T-500, T-800, T-1000, T-1300, T-1600

National (USA) : 7-P-50, 8-P-80, 9-P-100, 10-P-130, 12-P-160, 14-P-220

Oilwell (USA) : A-850-PT, A-1100-PT, A-1400-PT, A-1700-PT

Cameron-LEWCO (USA): WH1312, WH1612, W2200, W2214, W2215

MH Wirth (Germany): TPK-1600, TPK-2200

-

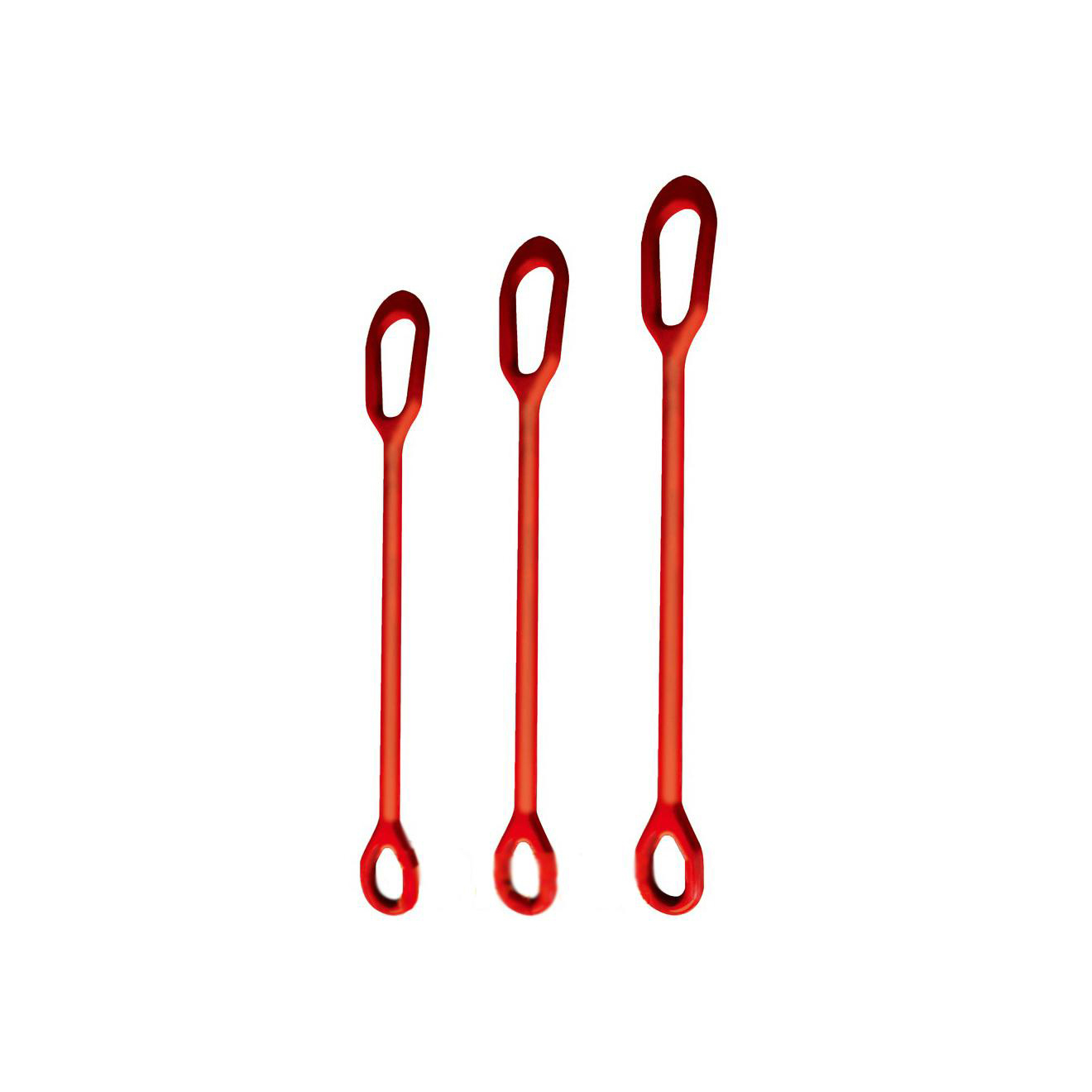

30180389 10490415-315 10490416-756 122599 TDS8SA TDS11SA Elevator Link for NOV VARCO TDS

VARCO:tds11sa,tds9sa,tds8sa,etc.

TESCO: HXI HCI HS ECI EMI EXI

CANRIG:1035 1050 1250 8050 6027

HH: DQ225DBZ DQ315DBZ DQ450DBZ DQ675DBZDQ900DBZ DQ225Z DQ450Z

JH: DQ40B DQ50B DQ50BQII-JH DQ70BS

BPM: DQ40BC DQ50BC DQ70BSH DQ70BSC DQ70BSD DQ80BSC DQ9OBSC

TPEC: DQ40AIII-A DQ40LHTY-LA DQ50II-A DQ50II-A DQ7011I-A DQ90I

Price and delivery: Contact us for detailed quotation

-

30180389 10490415-315 10490416-756 122599 Elevator Link for hanging Elevator from TDS8SA TDS11SA

VARCO:tds11sa,tds9sa,tds8sa,etc.

TESCO: HXI HCI HS ECI EMI EXI

CANRIG:1035 1050 1250 8050 6027

HH: DQ225DBZ DQ315DBZ DQ450DBZ DQ675DBZDQ900DBZ DQ225Z DQ450Z

JH: DQ40B DQ50B DQ50BQII-JH DQ70BS

BPM: DQ40BC DQ50BC DQ70BSH DQ70BSC DQ70BSD DQ80BSC DQ9OBSC

TPEC: DQ40AIII-A DQ40LHTY-LA DQ50II-A DQ50II-A DQ7011I-A DQ90I

Price and delivery: Contact us for detailed quotation

-

30172425 M611005624 30157226 30172425-DWG M614003435 TOROUE ARRESTOR,PIPE HANDLER NOV TDS PARTS VARCO

VARCO:tds11sa,tds9sa,tds8sa,etc.

TESCO: HXI HCI HS ECI EMI EXI

CANRIG:1035 1050 1250 8050 6027

HH: DQ225DBZ DQ315DBZ DQ450DBZ DQ675DBZDQ900DBZ DQ225Z DQ450Z

JH: DQ40B DQ50B DQ50BQII-JH DQ70BS

BPM: DQ40BC DQ50BC DQ70BSH DQ70BSC DQ70BSD DQ80BSC DQ9OBSC

TPEC: DQ40AIII-A DQ40LHTY-LA DQ50II-A DQ50II-A DQ7011I-A DQ90I

Price and delivery: Contact us for detailed quotation

-

30157226 120580 30157288 TORQUE ARRESTOR TDS8SA TDSPARTS NOV VARCO TDS11SA

VARCO:tds11sa,tds9sa,tds8sa,etc.

TESCO: HXI HCI HS ECI EMI EXI

CANRIG:1035 1050 1250 8050 6027

HH: DQ225DBZ DQ315DBZ DQ450DBZ DQ675DBZDQ900DBZ DQ225Z DQ450Z

JH: DQ40B DQ50B DQ50BQII-JH DQ70BS

BPM: DQ40BC DQ50BC DQ70BSH DQ70BSC DQ70BSD DQ80BSC DQ9OBSC

TPEC: DQ40AIII-A DQ40LHTY-LA DQ50II-A DQ50II-A DQ7011I-A DQ90I

Price and delivery: Contact us for detailed quotation

-

Manufacturer of Top Drive Drilling System series DQ30 DQ40 DQ50 with hook load 200T 250T 300T 350T

VSP TOP DRIVE Drilling SystemBased on rich experience in maintenance for Top Drives of various models of international brands and many years of production and sales experience,now VSP is launching a new project that integrates design, manufacturing, sales, and technical services—Our own Top Drive System; DQ20B-VSP,DQ30B-VSP,DQ30BQ-VSP,DQ40B-VSP, DQ50B-VSP, DQ50BQ-VSP, DQ70BS-VSP ,which are suitable for various types of drilling rigs.Max 500T Hook Load Capacity | 50 kN·m Continuous Torque | 75 kN·m Max Breakout TorqueThe Drilling well depth range is from 2000m-7000 meterEngineering Innovations for extended component life:Tilting Back Clamp (35% stability improvement)Gear-Rack IBOP Actuator (≤0.1mm precision)5 Redundant Hydraulic Circuits (100% signal reliability)Integrated Lower Balancing System (50% faster deployment) -

Packing Seals Kit 30123290-Pk / 30123440-Pk for Wash Pipe Assembly of Varco TDS Swivel Unit

The Wash Pipe Packing Kit is an essential component designed to ensure the effective sealing of the TDS wash pipe during rotation. This kit stands out with its exceptional features, boasting a trifecta of anti-wear, anti-pressure, and anti-corrosion properties. Furthermore, it offers unparalleled mechanical tenacity, making it a reliable choice for demanding applications.

Product Name: Packing, Washpipe, KIT, PACKING, PACKING, seal kit

Brand: NOV, VARCO, TESCO, TPEC, HongHua, BPM, JH

Country of origin: CHINA

Applicable models: TDS8SA, TDS9SA, TDS11SA, DQ500Z

Part number: 30123290-PK, 30123289-PK, 8721, 30123288, 30123286

-

NOV/Tesco TDS Service Loop 122517-200-25-3-B 30175017-86-4-3-B 124975-135-25-4B

Our company’s top drive service loop is crafted from meticulously selected imported materials. Each component, right down to the insulation layer of the lead-aluminum protective sheath, undergoes rigorous multi-layer inspection. The soft conductor and its outer sheath are expertly crafted, comprising numerous thin copper wires, with each strand showcasing a delicate arrangement of fine steel within the copper matrix.effectively minimizing friction during bending. Both ends are sealed with innovative high-hardness insulation materials to thwart water ingress. Before potting with chemicals like epoxy resin and quartz powder, we conduct thorough drying treatments to prevent unwanted bubbles and moisture from compromising the cable plug, with extra insulation and strengthening applied to the lead sheath’s edge.

30175017-75-4-3-B

30175017-86-4-3-B

M614002913-06-GLAND,1/2″NPT,EX,ARMORED-CABLE,NON-POTD (replaces 83444-04)

13088- KIT, SERVICE LOOP, SENSOR T 13088

87975-CABLE,2,4-COND,TW.PR,IND/SHIELD-PVC*SCD*

110076-(MT)CABLE,ARMORED,MULTI CONDUCTOR / SEE

115879-PLATE,MOUNT,CABLE (P)

118993-CABLE,INSULATED,1-CONDUCTOR

30156220-CABLE PROFIBUS + 3/C X ,075MM

30173477-646KCMIL POWER SERVICE LOOP, 4

-

Manufacturer of Nov 30157287 Clamp Cylinder Assembly (backup tong) on Torque Arrestor pH-75 30157288 for Varco TDS-11SA

A top drive clamp cylinder is a component of a top drive system used in drilling rigs. It’s a hydraulic cylinder that provides the clamping force to hold the drill string securely during drilling operations. Specifically, it’s part of the pipe handling mechanism within the top drive, allowing for the make-up and break-out of drill pipe connections

Clamp cylinders are typically integrated into the top drive’s pipe handling system, often alongside other components like link tilt systems and backup clamps. This clamping mechanism, powered by the hydraulic cylinder, contributes to the top drive’s ability to improve drilling efficiency, safety, and automation

30157287

301572263015728830160486 -

Hydraulic Pump/Motor Pn 109452/ 30158011/30151875/10377630 for Nov Top Drive

The Hydraulic Motor, a powerhouse of efficiency and reliability! This remarkable motor is engineered to drive the shot pin assembly, enabling seamless operation of the rotating head wheel gear and other hydraulic equipment. Masterfully connecting to a valve manifold, it delivers hydraulic power with unparalleled precision. Designed for low-speed, high-torque applications, it is the epitome of performance and durability.

109542

30158011

30151875-504

10377630-003

30156326-36S

P614000093

P614000121

-

Varco Wash Pipe 3″ / 4″ bore 30123289 / 30123289-TC / 30123438 for TDS-11sa

Wash Pipes are the integral components that ensure seamless operations in drilling environments. Under typical drilling conditions, mud pressure reaches up to 15,000 PSI. Traditional wash pipes, along with their packing, withstand these conditions for up to 800 operational hours. However, as pressures escalate beyond 5,000 PSI, traditional systems are prone to fail in less than 100 hours, with durability plummeting to mere 50 hours as pressure increases rapidly. the pipe system of the hydrodynamic variety excels by operating at pressures up to 15,000 PSI while significantly extending its service life. This means fewer operational interruptions and reduced risk for crew members during change-outs. With this advanced technology, maintenance can be scheduled more conveniently, avoiding the necessity to halt drilling operations and extract the drill pipe to replace a failed seal.

3″ bore : 30123289 / 30123289-TC

4″ bore : 30123438